If you’re part of the plastic processing industry, you’ve likely encountered the term ‘repeatability’ or at least heard it in passing. Even after searching the internet, you might still be wondering, ‘What is repeatability?’, ‘Why is repeatability important in injection molding?’, or ‘Why is there such emphasis on repeatability?’ In this article, we will try to answer these questions with thorough and insightful explanations. We will also offer practical advice on how to achieve and sustain a consistent and repeatable process in injection molding.

Repeatability: A Gauge for Injection Molding Machines’ Capability

Repeatability is a key indicator of production stability; it reflects the ability to consistently produce parts with similar features across different production periods. Typically, products from a highly repeatable injection molding process exhibit very similar dimensions, color, gloss, and surface finish, regardless of their molding time. While many of these aspects depend on raw materials, additives, auxiliary equipment, and other factors beyond the injection molding machine, the machine’s repeatability is primarily evaluated based on dimensional features and product weight.

The easiest and most common method for assessing the repeatability of injection molding is to measure the shot weight or product weight across different molding cycles. Once you have the shot or product weight data, calculating variation and standard deviation becomes straightforward. In a highly repeatable process, variation usually remains below 0.1% of the mean shot weight. Conversely, significantly higher values often indicate a lower level of repeatability. Most machine manufacturers prefer this method as it provides a non-comparative scale, allowing buyers to quickly gauge the machine’s repeatability.

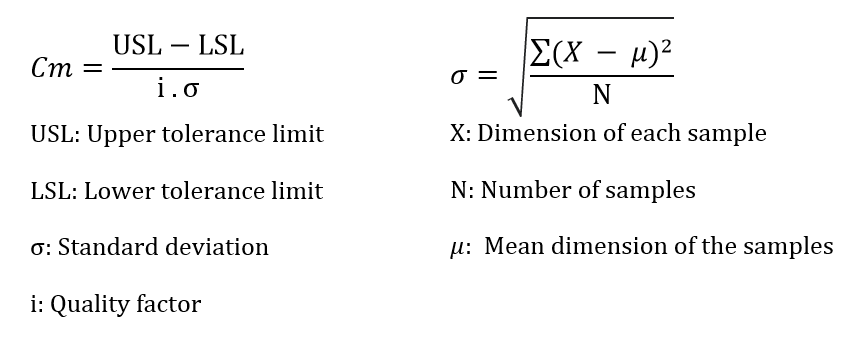

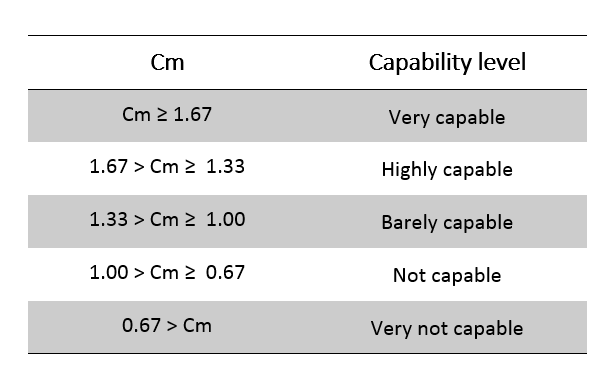

There is another method that assesses the repeatability of an injection molding machine through a machine capability study. This method is more popular among molders because it provides a comparative scale, allowing them to evaluate their machine in direct comparison with their other machines or even with the same machine across different production periods. The Machine Capability Index (Cm) is the primary indicator of repeatability in this method. It is derived from observing a specific feature in products from continuous molding cycles. To calculate Cm, at least 50 samples must be examined, and the formula used is as follows:

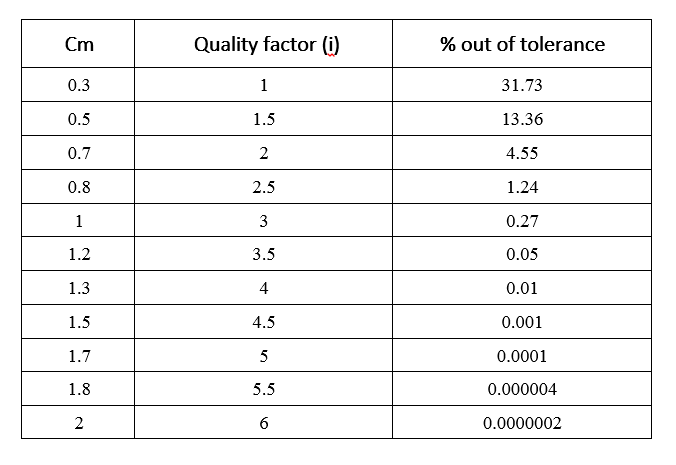

In a highly capable machine, the quality factor often equals 6, aligning the process with Six Sigma (6σ) standards. The quality factor is also linked to the number of out-of-tolerance products in the process; the higher the quality factor, the fewer out-of-tolerance products are produced.

The desired value of Cm is equal to or greater than 1.67, indicative of a very capable process or machine. Practically, it is not feasible to improve the Cm beyond 2.00.

For instance, in a Six Sigma process, if the Machine Capability Index (Cm) reaches 2.00, then only 0.002 products out of a million would be out of tolerance. This number is remarkably low, which is why there is no practical benefit to improving the Cm to values higher than 2.00.

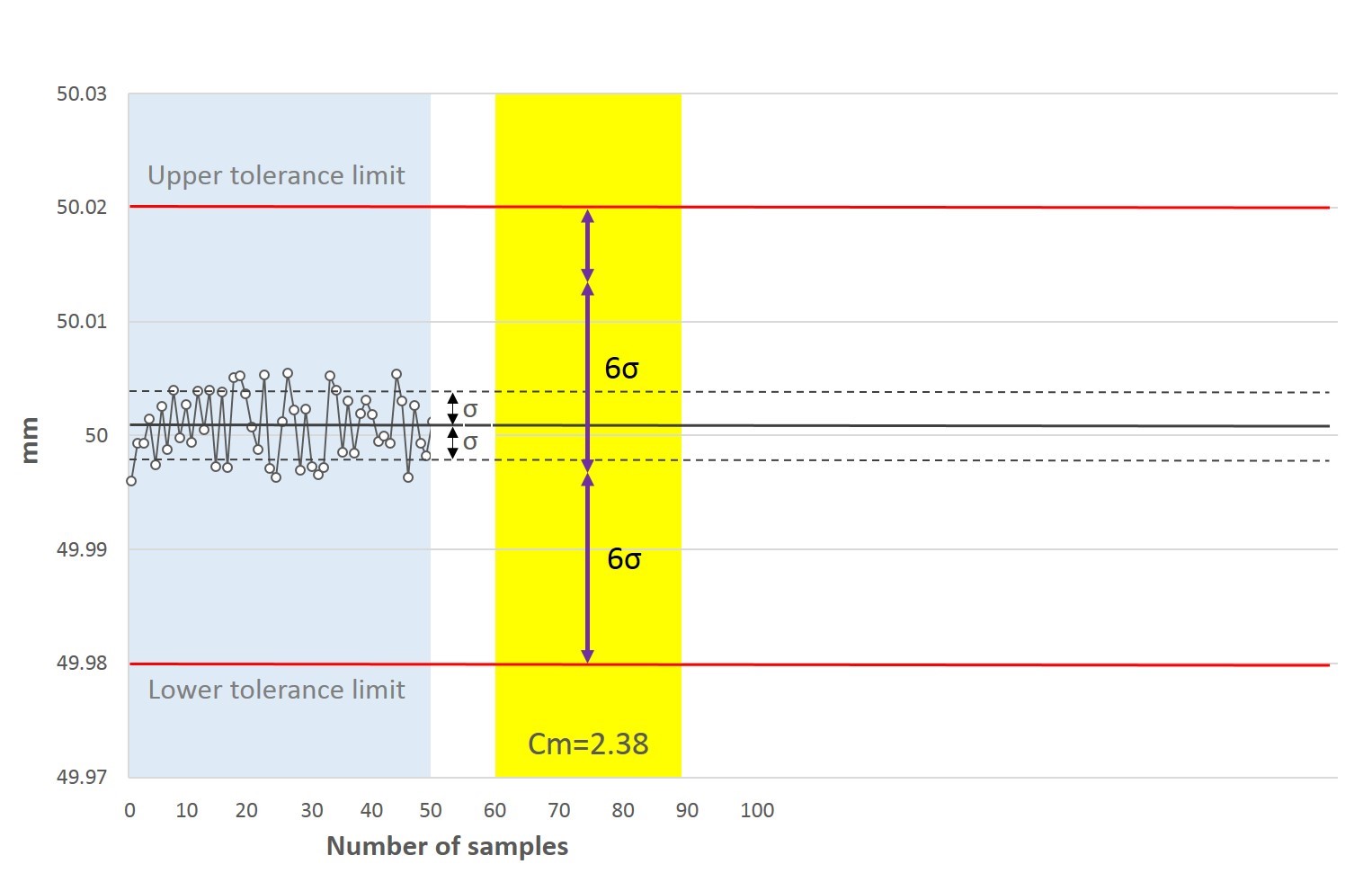

The diagram below shows the diameter measurements of several samples produced by a hydraulic injection molding machine across different production cycles. The nominal diameter of the product is 50 mm, with a permissible tolerance of ±0.02 mm. In this example, the Machine Capability Index is 2.38, which is exceptionally high, indicating that the machine’s repeatability is outstanding.

Strategies for Achieving Repeatable Injection Molding Processes

Utilizing a capable injection molding machine with high repeatability is essential for achieving a consistent molding process. Servo-driven hydraulic injection molding machines, equipped with closed-loop control systems, offer inherent accuracy and stability. Full-electric and hybrid injection molding machines, known for even greater precision and stability, are ideally suited for producing high-precision products that demand the utmost in process repeatability.

Highly capable injection molding machines guarantee repeatability over short periods; however, in the long term, several other factors must be considered. These include the rapid wear of injection unit parts, fluctuations in ambient temperature, unstable material properties, and more.

The one-way valve in the injection unit is susceptible to abrasion and corrosion. If it becomes worn out, the machine’s repeatability can be seriously compromised. In some cases, replacing the worn check valve alone can restore repeatability. However, more often, it is necessary to replace the entire screw and barrel set.

Factory temperature and humidity can vary at different times of the day or throughout the year. Many plastic processing factories do not practice ambient temperature and humidity control due to its high cost. To compensate for fluctuations in ambient conditions, some auxiliary equipment such as mold temperature controllers, chillers, dryers, and mold area dehumidifiers can be utilized.

Sometimes, material properties vary from batch to batch, leading to unstable product quality. Consequently, adjusting the machine settings becomes inevitable with each new material batch. One remedy for this issue is to use higher-quality, more stable materials, although this could undesirably increase production costs. Another solution is to exert greater control over the material by using auxiliary equipment, such as pellet dryers and gravimetric dosers.