“On May 21, 2025, YIZUMI inaugurated its Turkey Technical Center in Silivri, Istanbul, strengthening local manufacturing, accelerating service response, and supporting global growth.”

On May 21st (local time), Yizumi Turkey Precision Makine A.S. (YIZUMI Turkiye Technical Center) hosted a grand opening event in Silivri, Istanbul, attended by industry experts, partners, and customers.

Strategic Milestone in Globalization

At the ceremony, Mr. James Zhang, Deputy Managing Director of YIZUMI, and General Manager of both the Injection Molding Machine Division and the International Business Division, delivered a welcome speech. He emphasized that the establishment of YIZUMI Turkiye represents a significant milestone in the company’s globalization efforts. This development marks substantial progress in YIZUMI’s strategic expansion across the Middle East and Africa regions. Moreover, it is a crucial step forward in the company’s localization strategy and fosters synergistic development between the Asian and European markets.

01.「Operation Strategy」

Unlocking New Global Hub in Turkiye

In recent years, Turkiye’s strategic trans-Eurasian geographical position, combined with its continuously improving investment policies, has attracted global manufacturers to accelerate their overseas expansion. This trend has significantly boosted the demand for medium- and high-end manufacturing equipment. Beyond being one of the world’s major automotive production hubs, Turkiye has also become a crucial base for European manufacturers in home appliances, furniture assembly, pharmaceuticals, and packaging sectors to relocate and expand their production capacities.

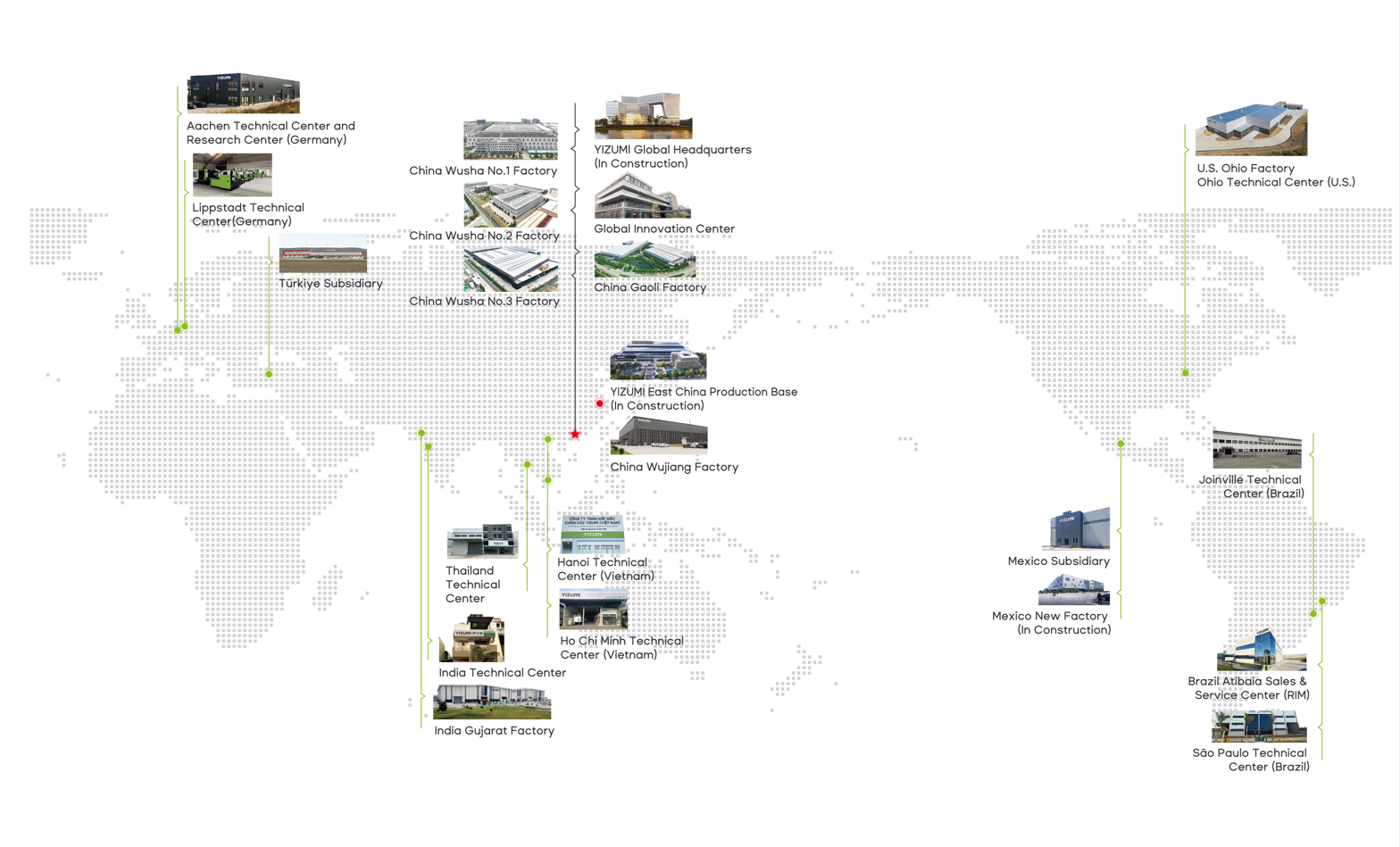

Leveraging deep market insights, YIZUMI has made the strategic decision to establish a subsidiary in Turkiye. This move aims to support industrial clusters across Eastern Europe, tap into the engineering plastics market driven by the Middle East’s energy transition, and capitalize on North Africa’s emerging manufacturing growth potential. Furthermore, the Turkiye subsidiary will serve as a central hub for integrating technical resources in Europe and effectively responding to the ongoing restructuring of the regional industrial supply chain.

“In terms of our overseas development strategy, we have positioned this subsidiary as a technical service center for the Middle East and African markets, as well as a hub to serve customers across Europe, Asia, and Africa,” stated Mr. James Zhang. He further confirmed that this strategic layout aligns closely with Turkiye’s 2030 Industry and Technology Strategy, which emphasizes the localization of high-end equipment manufacturing. Through its subsidiary in Turkiye, YIZUMI aims to strengthen its connection with local customers and optimize its services, delivering faster and more efficient support tailored to their needs.

02.「Localization Layout」

Building New Competition Edge with Faster Response

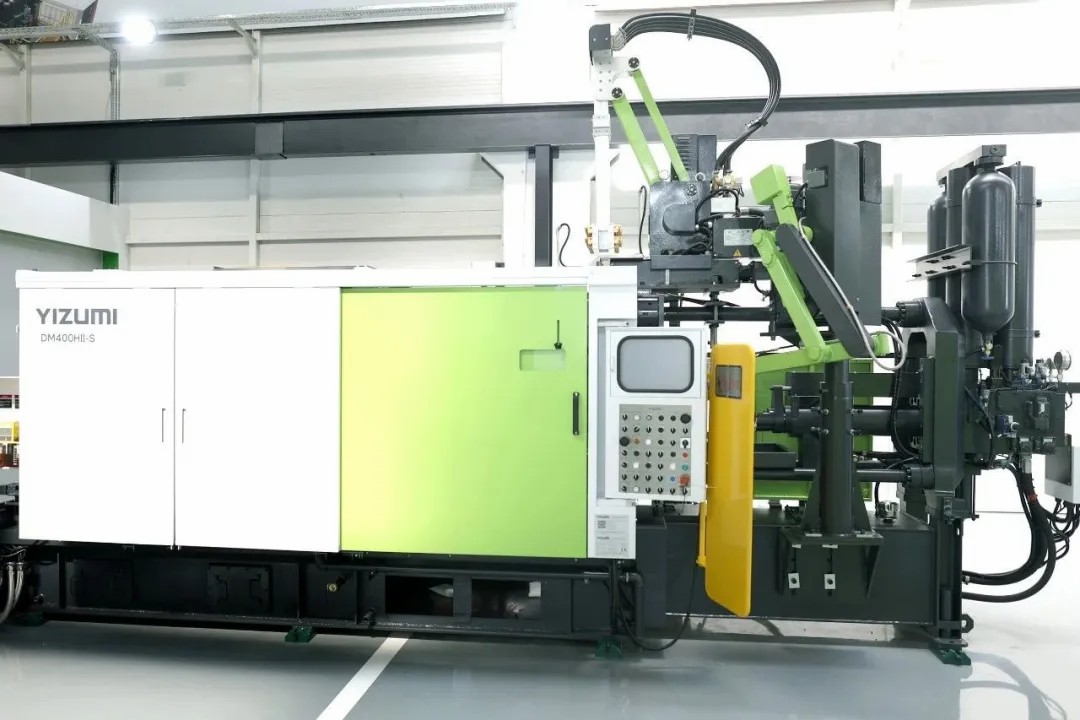

At the Open Day event, visitors will have the opportunity to explore the impressive YIZUMI Turkiye Technical Center, which spans 2,000 m². The showcase features over ten machines, including injection molding machines, die casting machines, rubber injection machines, and the SpaceA Industrial 3D Printing Machine — all demo-producing turnkey solutions for daily necessities, auto parts, and medical care products. Additionally, local engineering teams are on standby to respond promptly to any emergencies, supported by a smart warehouse that accurately stores thousands of key spare parts.

A Middle Eastern plastic product manufacturer, after closely observing YIZUMI’s equipment, shared: “Previously, we had to wait two weeks just for spare parts when using imported equipment. Now, with YIZUMI’s spare parts warehouse and engineering team in Turkiye, we feel reassured about long-term cooperation.” This sentiment reflects a widespread challenge faced by global manufacturers: when downtime losses are measured in minutes, rapid service response becomes not just important, but essential for maintaining seamless operations.

YIZUMI’s mission goes beyond accelerating after-sales response — it is committed to delivering long-term ecological value. The company aims to become a strategic technology partner for the regional manufacturing industry by offering comprehensive technology support and integrated services throughout the entire equipment lifecycle.

Today, an industrial service network is rapidly taking shape across Asia, Europe, and Africa, driven by the localized operations of YIZUMI Turkiye in collaboration with its local partner, General Makina. The subsidiary has already addressed specialized needs such as the lightweight transformation of the automotive sector in the Middle East and the modernization of the packaging industry in Eastern Europe, delivering customized turnkey solutions tailored to local customer demands.

03.「Development Driver」

Accelerating Market Penetration with Advanced Technology

YIZUMI’s global strategy focuses on building an integrated worldwide network that combines research and development, manufacturing, and services — enabling efficient resource allocation and collaborative operations across regions. In line with this vision, the company will further accelerate its localization efforts in overseas markets throughout 2025, with YIZUMI Turkiye playing a vital role as part of its expanding global operations.

In Europe, the YIZUMI Aachen Research Center in Germany serves as a key engine of the company’s global technological innovation. It enables the rapid transformation of R&D achievements into practical applications, allowing YIZUMI to respond more swiftly to evolving global market demands. The establishment of YIZUMI Turkiye is expected to create strong synergies with the German center, enhancing the company’s service capabilities and response speed across Europe, while also accelerating the transfer of technical advancements into the Middle East and North Africa markets.

Mr. James Zhang envisions a future where more devices proudly bear the YIZUMI logo across this continent. “When China’s intelligent manufacturing meets the robust dynamics of Europe and Asia, a new era of high-end equipment emerges. This involves not only the export of machinery, but also the deep integration of technology, philosophy, and culture. YIZUMI is beginning a new chapter here—one that will contribute significantly to the advancement of the global manufacturing industry,” he emphasized.

Conclusion: Strengthening Global Manufacturing Through Localized Innovation

The launch of the YIZUMI Turkiye Technical Center represents more than just a physical expansion — it embodies a forward-looking vision: to build a globally connected, regionally responsive, and technologically advanced manufacturing support ecosystem. As YIZUMI deepens its localization strategy in key markets, it is positioned to deliver faster service, smarter solutions, and forge strategic partnerships across three continents.

With this milestone, YIZUMI not only strengthens its presence in Europe, Asia, and Africa but also sets a new benchmark for intelligent equipment providers navigating an increasingly dynamic industrial landscape.

Source:

https://www.yizumi.com/en/news/company/yizumi-turkiye-technical-center-launch-opening-a-new-global-era